WGB-090

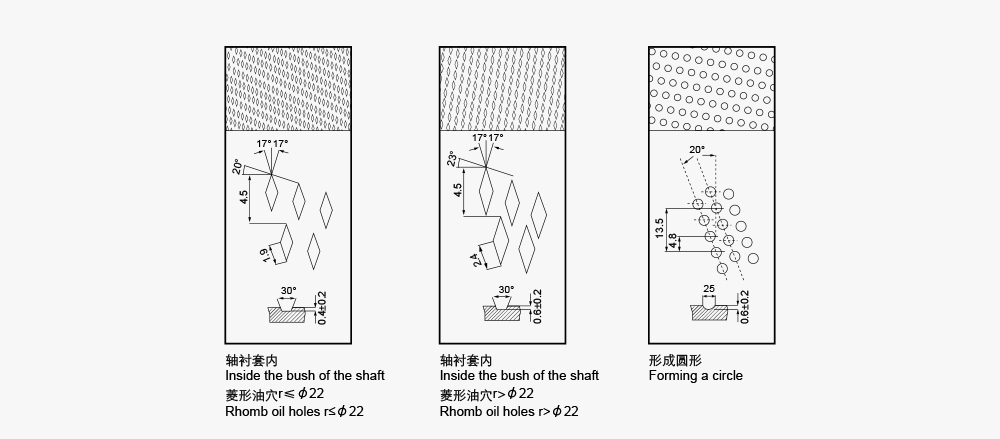

WGB-090 Bronze-Wrapped Bushing,Using a special formula of high-density copper alloy strip as the matrix, the surface can be rolled with diamond or hemispherical oil pockets and oil grooves according to user requirements. It has the advantages of high density, large carrying capacity, good wear resistance and long service life. It can replace the traditional cast copper sleeve, which can reduce the mechanical volume and reduce the cost.

WGB-090 Material structure and available form

It is made of high-density bronze rolls or spherical oil bags, and special synthetic internal surfaces with oil pockets to reduce wear and extend the use time and achieve good anti-corrosion function.

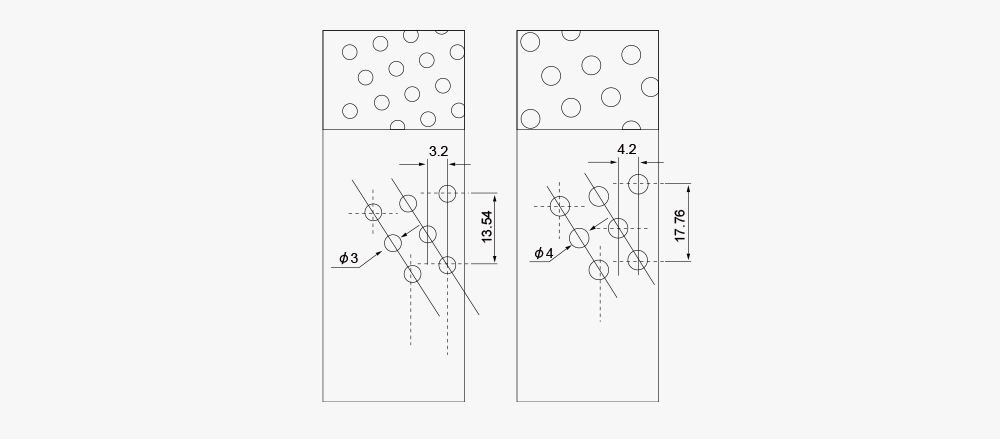

WGB-092 Material structure and available form

It is made of high-density bronze rolls or spherical oil bags, and special synthetic internal surfaces with oil pockets to reduce wear and extend the use time and achieve good anti-corrosion function.

Product advantages

It is made of high-density bronze rolls or spherical oil bags, and special synthetic internal surfaces with oil pockets to reduce wear and extend the use time and achieve good anti-corrosion function.

1. Save a lot of copper materials and save man-hours for car-making copper sleeves:

2. Compared with vehicle-made shaft sleeves and rolling bearings, it is lighter in weight and lower in cost;

3. Various holes, pits, and certain grease can be processed on the friction surface, and the time for refueling is 5 times longer than that of the copper sleeve;

4. Very high load capacity, especially suitable for rough friction surfaces;

Products available: straight sleeves, thrust washers, flanged bushes, bearing bushes, sliding plates, steel sleeve assemblies.

Standard bushing tolerance

Nominal thickness |

Outer diameter |

Matching seat hole |

inner diameterf | Shaft diameter |

10~18 |

+0.065 +0.030 |

+0.018 0 |

+0.046 0 |

-0.016 -0.043 |

18~30 |

+0.075 +0.035 |

+0.021 0 |

+0.052 0 |

-0.020 -0.020 |

30~50 |

+0.085 +0.045 |

+0.025 0 |

+0.062 0 |

-0.025 -0.064 |

50~80 |

+0.100 +0.055 |

+0.030 0 |

+0.074 0 |

-0.030 -0.076 |

80~120 |

+0.120 +0.070 |

+0.035 0 |

+0.087 0 |

-0.036 -0.090 |

120~180 |

+0.170 +0.100 |

+0.400 0 |

+0.100 0 |

-0.043 -0.106 |

180~250 |

+0.210 +0.130 |

+0.046 0 |

+0.115 0 |

-0.050 -0.122 |

250~315 |

+0.260 +0.170 |

+0.052 0 |

+0.130 0 |

-0.056 -0.137 |

Tech. Data

|

Relevant data |

WGB-090 | WGB-092 |

WGB-09G |

|

Material |

CuSn8P0.3或CuSn6.5P0.1 |

CuSn8P0.3或CuSn6.5P0.1 |

CuSn8P0.3或CuSn6.5P0.1 |

|

Max.load |

75 |

60 |

65 |

|

Hardness |

90~120 |

90~120 |

- |

|

Temp. limit |

-80~200 |

-100~200 |

-100~260 |

|

Max. Sliding Speed |

2.5 |

2.5 |

4 |

|

摩擦系數(shù) |

0.08~0.25 |

0.08~0.25 |

0.06~0.20 |